What to See, Experience, and Explore at Miami Art Week 2025

We checked in with our former podcast guests who will be inching through Miami traffic, unveiling new works, signing books and revealing new projects this year.

This article is from our first-ever print issue, available for order online now.

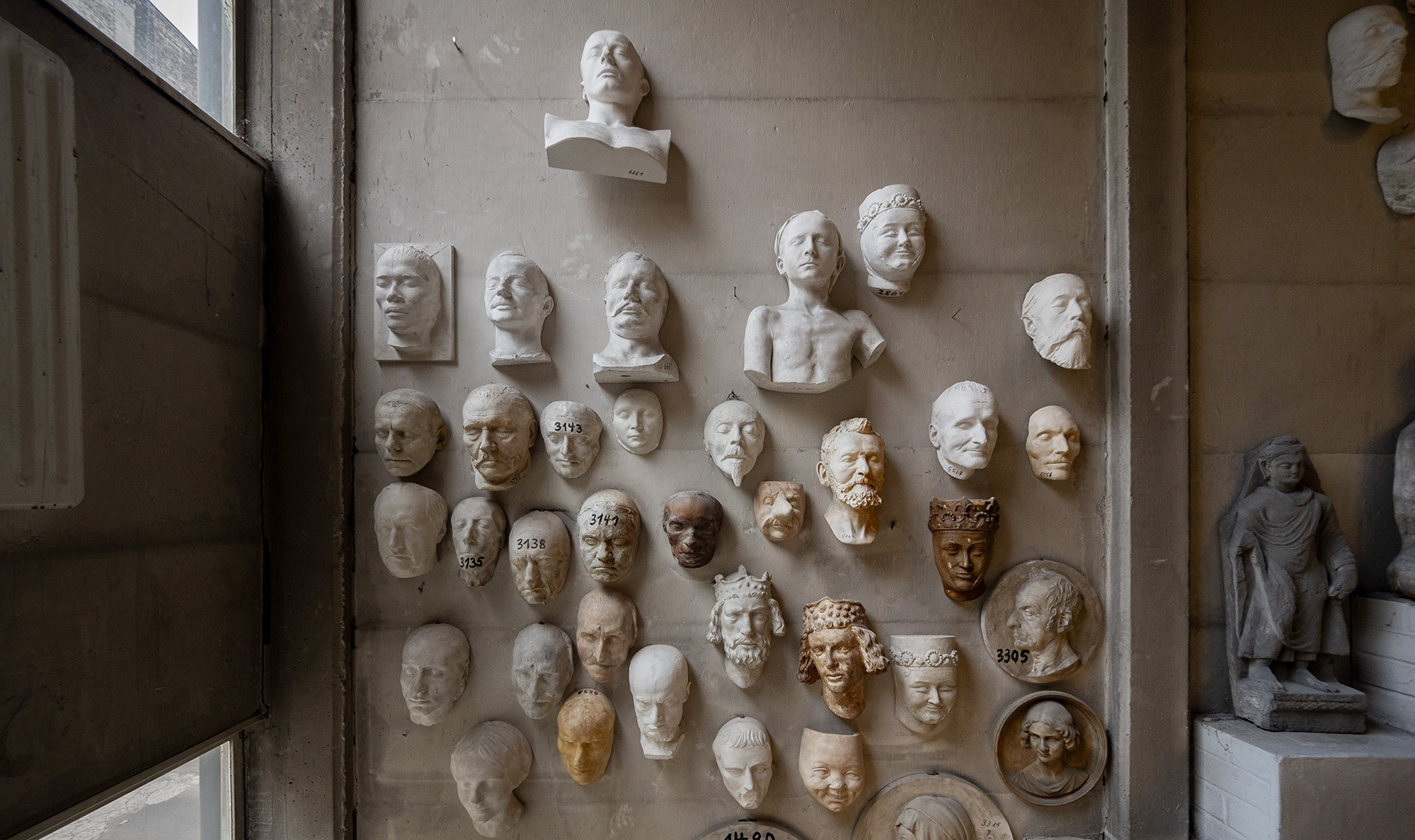

It’s difficult to understand just what Berlin’s Gipsformerei is even from its title, which roughly translates to “replica workshop,” in the context of today. “Most people think that we produce copies,” says director Miguel Helfrich, but that would be a reductive take. Historically, the institution specialized in plaster casting, a process popular in the 19th century that involved making a three-dimensional mold of an object—whether a sculpture or a crocodile—from which you could cast a replica. Plaster casts have traditionally played a central role in art history and museum practice, but today, it’s an outdated technique.

Founded in 1819 in Berlin’s Charlottenburg neighborhood, the Gipsformerei is one of three institutions left of its kind (the others are in Paris and Brussels). One of the city’s Royal Museums as of 1830, this anachronistic survivor is “a mixture of traditional museum collection, manufacturer, and art restoration center,” says restorer Marcin Korbanek. The institution houses over 7,000 molds, but its purpose skews toward preserving these molds rather than creating new ones.

Clients range from museums, often within the network of the National Museums in Berlin, including the Sculpture Collection and Museum of Byzantine Art, which holds a huge collection of works heavily damaged in World War II, to private clients like American artist Jeff Koons. They can order casts made from one of the existing molds, with practical implications ranging from replacement parts for existing sculptures to bolstering educational and private collections to tactile models for the blind. “We conserve a time capsule,” says Helfrich. For example, “If a customer ordered a piece of the Parthenon frieze, they don’t get the Parthenon frieze how it looks today. They get a piece of how it looked in 1882.” Ahead, I spoke with Helfrich, Korbanek, and curator Veronika Tocha about their mission, the process and implications of conservation, and their contrast with the looming shifts of the digital age.

How did this institution get started?

Miguel Helfrich: The Gipsformerei was founded in 1819 by King Friedrich Wilhelm III as the Königlich Preußische Gipsgussanstalt (Royal Prussian Institute of Plaster Casting). It joined the Royal Museums in 1830. Its foundation was one of many initiatives to promote the arts, sciences, and industry that were undertaken by the state of Prussia after its victory over Napoleon. The Prussian state hoped that the manufacture of replicas would provide it with a new source of income. This all happened after the model of the Parisian atelier de moulage, founded in 1794 and associated with the Louvre. Casts were popular at least since the late 18th century in Western Europe, and the European centers founded their own factories to enrich their museum collections, but also to compete internationally and gain power. We have existed for more than 200 years, so our molds and models are very old. This is what makes our work fascinating. We conserve a time capsule, if you will. We are able to reproduce a piece at the age its mold was initially made.

Veronika Tocha: There’s this idea of originality or authenticity you have brought up. In the 19th century, mold-taking was very close in terms of timing to the original. Now, time has passed. The originals have changed. The mold has also perhaps changed a bit. There have been more generations— whether it was molded from the original or a model of the original—of molds. In the 19th century, plaster casts had a far greater meaning than nowadays. At that time, museums and university collections were full of casts. They were highly appreciated. In the 20th century, there was a decline in appreciation, and they were discarded and thrown away. Many cast collections ended up damaged or as rubbish. We are kind of an anachronistic survivor of this 19th-century plaster-casting period, and we have new purposes today. As Miguel said, there’s renewed interest in casts in terms of this capsule of time we conserve with the molds.

How would you differentiate its purpose in 1819 from that of today?

Marcin Korbanek: One of the biggest differences between 1819 and today is that we don’t produce new molds from objects that are a part of collections in museums. We have around 7,000 molds in our collection, but nowadays it’s near impossible to make a mold of an object in a museum because it’s too risky. We perceive molds and models as part of a collection, as objects, not just as tools.

MH: To this day, we continue to use our historic piece molds, which form an essential part of our collection. However, their dual role as both artifacts and tools requires a careful balance between preservation and utilization, with the conservation of these molds being our top priority. The repeated use of a mold inevitably leads to wearing out, causing damage, chipping, or the abrasion of its structure. For this reason, it may become necessary to discontinue the use of the most valuable molds for casting. When historic molds can no longer be used for conservation reasons, we seek alternative solutions. One such approach is creating new molds; however, this is a costly and time-intensive process, particularly for large-scale molds.

We do, however, still receive requests from museums for reproductions. Following an analysis of the original, we create a molding plan. When contact-based methods are unsuitable, we use contact-free techniques to balance preservation with the creation of high-quality reproductions.

Tell me a bit about the process. How do you make a mold and then the subsequent plaster cast?

VT: We have three kinds of molds. The plaster-piece molds, the gelatin molds, and the silicone molds. The quality of the cast is always defined by the state of the mold but also by the type of the mold. We have different generations of molds. It’s always a discussion about what is more important: the model or the mold. We always put the focus on the mold.

MK: Other institutions work mostly with silicone. We are one of the few that still work with gelatin. You need to have a lot of experience to know how to do it. We start with a model that goes into a firm. Then you pour in the gelatin, which is a mixture of bond glue and glycerin. Every time you want to make a new gelatin firm, you are producing the new firm from the model. A cast is something that we produce and sell to customers. The model is something that we use to produce the firm.

Also, plaster-piece molds are very hard to work with. After you make a cast from a plaster-piece mold, you need to do a retouching because this mold consists of many different plaster pieces. Where they come together, you usually have a seam. You need to sand it. You need to work with small tools like the ones dentists use. We have people who have done this for 30 years. This is kind of a profession that is dead nowadays. We are one of few places that has this technology, so education is also important.

What are your personal highlights in the collection?

VT: Generally speaking, we have more than 7,000 molds and models from throughout history until the early 19th century. It’s like a global art history. Of course, there is a lot of Eurocentric art history, because people molded the stuff they found important in the 19th and 20th centuries, but the collection’s not curated. It’s a wild-style range. For example, we have a huge collection of non-European art, which isn’t often highlighted because traditional plaster-casting collections used to focus on antiquity or European art history. We have a really wonderful collection of Mesoamerican art.

As the curator, I find the objects most interesting in terms of object biography. I try to look at the object itself, instead of looking through it and just seeing the original. The model or the mold tells a story. We have the Portrait Bust of a Princess from Naples by Francesco Laurana, an Italian Renaissance sculptor, molded in the 1880s. The bust was divided into two pieces when it was decapitated in the Second World War. The head itself stayed in Berlin and the shoulders went to the Pushkin Museum in Moscow. So we have a shared history with the Russian colleagues there, because none has the complete artwork. We have a historical plaster-piece mold here. For the Bode-Museum in Berlin, we cast the shoulders, and for Moscow we cast the head. It’s a beautiful bust, but it’s also a beautiful story.

MH: I think this is a very good example, because you could now ask, “Where is the original? Is it in Moscow? Or maybe in Berlin? Or is it in our house?” Because you have different ways to view this word, original.

Obviously you have the cast itself, but what work goes into the surface-level appearance?

MK: I’ll answer because I used to work as a painter before I got this job. A cast will never be exactly like the original object from which it was molded, but our painters attempt to imitate the look of the original substance. They imitate different kinds of materials, like marble, travertine, alabaster, limestone, steel, or brass. For example, to imitate alabaster, you need to apply many glazes to achieve a three-dimensional effect on a flat surface. In the case of alabaster or marble, we use paints based on natural and acrylic resins, which we produce ourselves. Sometimes these replicas are very faithful to the originals. Other times when, for example, the ancient sculpture no longer exists and we only have old black-and-white photographs, we create imitations in the style of ancient marble.

Some of these originals are 5,000, even 6,000 years old. You don’t need to imitate only the material, you need to imitate all of the dirt layers or oxidation when it comes to metal objects. We do it by using different binders. This is also part of what we are trying to research now, to find out what kind of binders our ancestors used to work with, trying to understand why objects age differently. Unfortunately, not all of the knowledge survived.

MH: For example, the first replica of the Bust of Nefertiti was created in 1913, just a few months after its discovery, making the process of copying an inseparable part of its presence in the collections of the Berlin State Museums. Over the years, many different versions were produced in the Gipsformerei’s workshops. Today, our goal is to create the best reproduction of this sculpture in the world. A key aspect of this endeavor is the coloration, for which we developed a special technique over a two-year development process. Color studies were conducted, and a method for applying layers and creating texture was developed. Based on analyses of the original, we established the technology for the original polychromy, which is also applied in the production of our reproduction.

Obviously, the digital world is getting bigger and better every day. What sort of threat, if any, does that pose to your work?

MK: When I started in art restoration maybe 16 years ago, the discussion had already begun. We were afraid we wouldn’t be useful anymore, that we would get replaced by 3D printers. It’s 2024, and they’re still not perfect enough to do our job fully. Maybe one day they will be, especially now that we have AI. But so far, we are still better.

MH: We’re collaborating with the Technical University of Berlin in the field of 3D technology. There are benefits. For example, when an old material can’t be touched, it’s very useful to do things digitally. In a lot of projects, we mix traditional techniques with 3D scans. All the techniques that we use have benefits and disadvantages, so we try to find the best combination from all the available techniques that we have.

VT: Of course we live in a digital era, but people love analog techniques, handcrafting. They come here, and they see people working with their hands, and everyone says, “Oh, this is such a nice job. I want to work here.” There is some sort of longing for working with the hands in digital times, which I think will stay.

What’s the training like to work with these precious molds and models?

MK: Some of our painters studied art restoration. Some of them studied theater scenography or painting. Some of them were church painters. There are some professions that are not that far from what we do, but no specific profession or school for people to get the specific qualifications to work in the Gipsformerei. We are trying to cooperate with art schools to offer internships, but there’s no specific program yet.

VT: There are many stucco plasterers. Bronze casters, also. They then come and undergo a special traineeship to specialize in artistic plaster casting.

How do the plaster casts or the molds transcend the idea of an original and start their own life, in a sense?

VT: When I look at my field of work, I try to reattribute authorships. Every cast, every mold and model was made by a person. Sometimes we know them. Sometimes we have signatures on the models or the molds. The craftsmen making these pieces understood themselves as artists or as subjects of authority. Nowadays, this is what interests us. We try to find out when these pieces were made. We try to date them. We try to do exactly what another curator or another person in the museum does: give the pieces data. We attempt to uncover what material was used, what kind of coatings, what kind of traces were left on the surfaces of the molding processes in the past, which generation it’s from. We do not just see these pieces as tools.

MK: We even try to avoid using the word original in the case of objects that have been molded. To us, they are not copies and originals. Additionally, some of our casts or models were made on human beings, on animals, like a copy of a crocodile, for instance.

Is there any stipulation on how many copies or casts you will make from a single mold?

MH: At all times, there is a limited number. For example, our reproductions of Nefertiti are crafted to an exceptionally high standard. As a result, our output is limited, and we are only able to produce 10 to 15 pieces per year. You have to remember that we offer 7,000 different objects, and most of these objects do not receive many orders. Nearly every reproduction is typically a bespoke commissioned piece. Each commission is unique in its own way and is crafted with great care by hand. While the primary focus is on faithfully replicating the original template, the individual character of the artisans who create the piece is subtly reflected in the work.

VT: We have pieces that have been sold several hundred times, maybe even 1,000 times. And then there are others that have been sold only once. We have some kind of sales book that records the sales in the first half of the 20th century, but we can’t identify how many casts we sold in the 19th. Sometimes we find casts in other collections with our little Gipsformerei stamp. Or we know that a cast was sold here or there. But they’re not so easy to trace. There are whole research projects in finding all the casts the Gipsformerei made in the past.

MH: Exclusivity isn’t our goal. Of course, we can make limited editions, but it’s not our main target. Money and time are limitations, of course, but internally, we want to be open to everybody.

We checked in with our former podcast guests who will be inching through Miami traffic, unveiling new works, signing books and revealing new projects this year.

The ecstatic designs of Chris Wolston come to Texas, Juergen Teller's most honest show yet opens in Athens, a forgotten Cuban Modernist is revived in New York, and more.

Tom Sachs explores various creative disciplines, from sculpture and filmmaking to design and painting. On this season finale, Dan speaks with Tom about his accidental journey to fine art, how an installation in a Barneys window kickstarted his career, and more.